In stock / Shipping Available

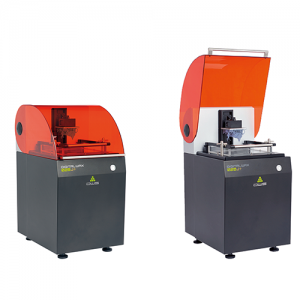

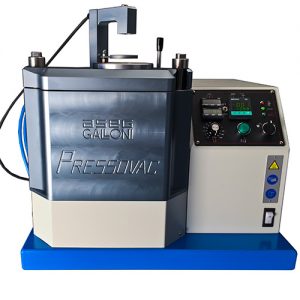

“G” SERIES VACUM “OVER PRESSURE” CASTING MACHINES

The operator has simply to charge the crucible, place the casting flask in position and press one button! All machines lead the operator logically step-by-step through the casting sequence, irrespective of the type and quantity of the alloy. Frequency and power output are automatically and continuously adjusted and, just ahead of attaining the preset casting temperature, the computerized control starts modulation of the heating current by delivering low frequency impulses, thus inductively stirring the melt. Then, when all parameters are achieved and the temperature “spread” is no more that 4°C either side of the set point, pouring starts automatically followed by strong pressurization of the molten metal by inert gas. The complete cycle can be performed in minutes and crucible lasts for hundreds of casting it properly used.

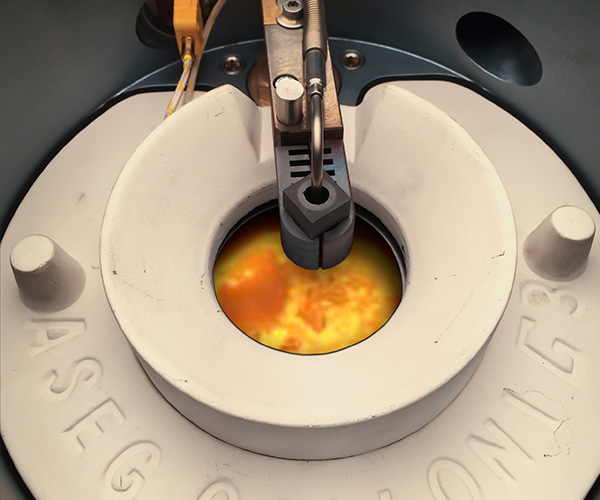

EXPLANATORY NOTE OF THE “OVER PRESSURE” GAS IN MOLTEN METAL

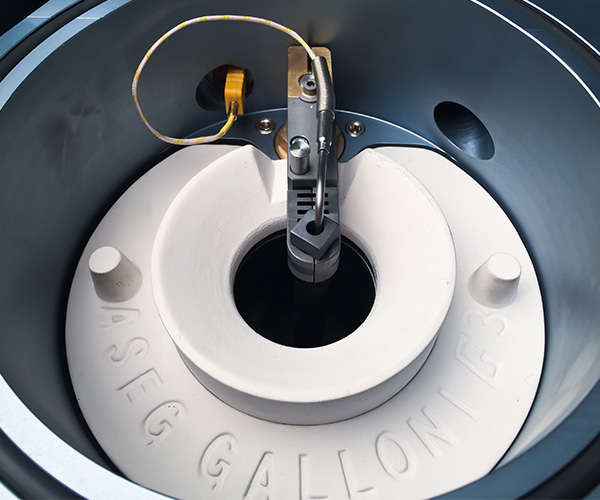

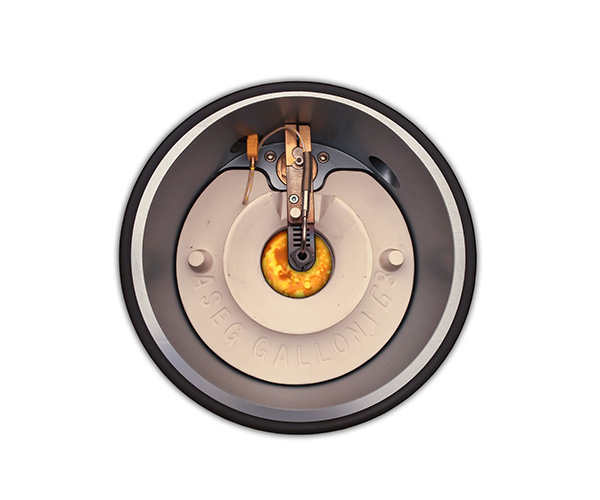

In our system both the flask and crucible are located in a common chamber which is first fully evacuated by vacuum, before melting, followed by helium gas supply to create an inert atmosphere. Helium gas presents excellent gas fluidity which provides a cleaning effect of the molten metal and flask and guarantees a smooth filling of metal even with the most intricate filigree patterns.The casting temperature is attained and low frequency pulses are given to vibrate and mix the molten metal by keeping it homogeneous. At this stage the flask is pushed against a long lasting special metal sealing blade system, or SBS, which, like a knife , cuts the investment by sealing the vacuum underneath the flask. This “long lasting” system avoids the use of silicon gaskets or flasks with flange with an important reduction in casting costs. The metal, once completely poured into the flask, is pressurized by argon up to 4 bars. This pressure being applied to the molten metal, forces it into the flask while the vacuum pulls it. This results in a very smooth surface due to the effect of the vacuum and a dense well compacted casting due to the over- pressure which benefits both thin and thick sections.

鑄造機優點

- Redesigned metal rod (plunger) holder enables rod changeover in seconds and does not involve expendable components. Redesigned smooth discharge pure graphite crucible.

- “Sealing Blade System” (SBS) guarantees perfect flask seal without the use of silicone rubber gaskets.

- Perforated or unperforated flasks WITHOUT FLANGE enabling greater furnace flask capacity.

•Crucible Volume:240 cc

•Crucible Life Time:80 ~ 150

•Capacità Di Fusione / Casting Capacity:

Au 24 kt min. 200 g – max. 3500 g

Au 18 kt min. 200 g – max. 2200 g

Au 14 kt min. 200 g – max. 2000 g

Au 9/10 kt min. 200 g – max. 1800 g

Ag min. 200 g – max. 1900 g

Al min. 200 g – max. 500 g

•Flasks:Ø min. 80 mm – Ø max. 150 mm / h min. 80 mm – h max. 300 mm

•Working Frequency:10 kHz

•Max Temperature:1150 °C “K”/ 1450 °C “S”

•Water Cooling Supply:ad acqua, 3 l/m – 3 bar; 20 – 25 °C; Acqua demineralizzata con resistività maggiore di 20K ohm/cm / by water, 3 l/m – 3 bar; 20 – 25

°C; demineralized water with resistivity over 20K ohm/cm

•Compressed Air Supply:7 bar

•Inert Gas Supply:Argon, Azoto, Elio / Argon, Nitrogen, Helium

•External Vacuum Pump:esterna 60 m³/h / external vacuum pump 60 m³/h

•Overall Dimensions:base 600 x 650 mm – h 1200 mm

•Weight:222 kg

•Guarantee:12 mesi (solo se usati consumabili originali Galloni) / 12 months