In stock / Shipping Available

CASTING CYCLE

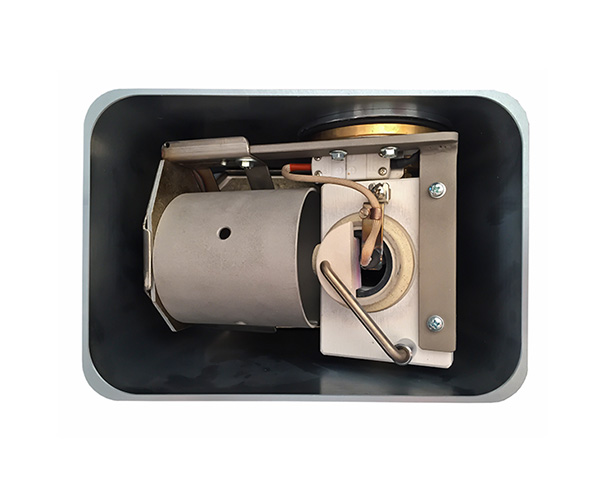

The casting chamber is fully evacuated by vacuum before melting, followed by helium gas supply to create an inert atmosphere.Helium gas has an excellent gas fluidity which provides a cleaning effect of the molten metal and mould and guarantees a smooth filling of metal even of the most intricate patterns.The casting temperature is attained and low frequency pulses are given to vibrate and mix the molten metal by keeping it homogeneous. Temperature is controlled by an optical pyrometer up to 2100°C for platinum and steel and by an immersion type “S” thermocouple inside the graphite crucible up to 1450°C for gold,silver and bronze.

At this stage, just by pushing a button, the whole crucible/flask system will automatically rotate 90° and the metal, once poured in an homogeneous and controlled way into the flask, it is automatically pressurized to 4 bars by argon gas.This high and quick pressurization is indispensable to obtain a proper and homogeneous filling, even at low metal/flask temperatures, for gold, silver and bronze alloys and, above all, for platinum and special steels which have a very narrow melting interval, thus a very quick solidification. This results in a very smooth surface due to the effect of the vacuum and a dense, well compacted casting due to the “over pressure” of 4 bars, which benefits both thick and thin sections.

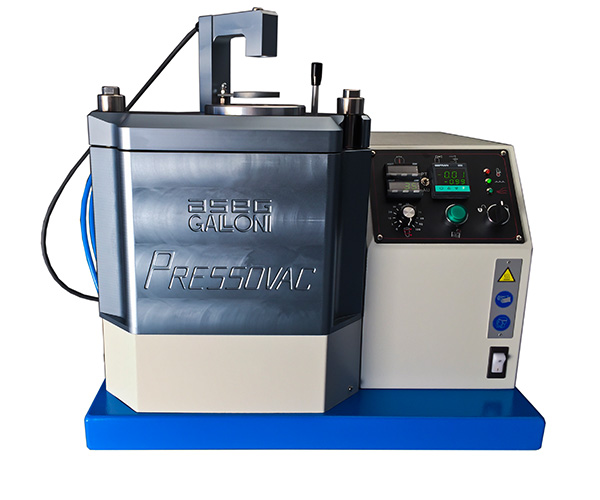

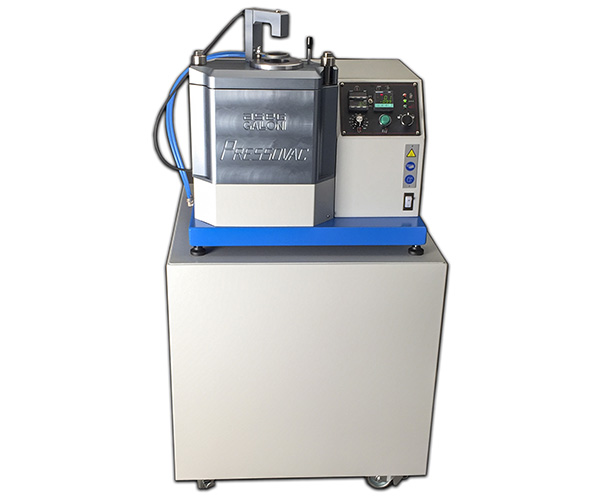

The system used by our Pressovac series casting machines was specially developped for dental labs where casting perfection is absolute: casting pieces have a very smooth surface, a very dense molecular structure and without defects like unproper filling,porosity and shrinkage. Metal is inserted into the crucible and the flask positioned on the cradle inside the casting chamber.

The “DUAL PYROMETER” version of our well-proven Pressovac machine features:

• Optical infrared pyrometer for platinum and steel casting up to 2100 °C

• Immersion-type “S” thermocouple for gold and silver casting up to 1450 °C

FEATURES OF THE PRESSOVAC SERIES

• Extremely robust water-cooled casting chamber

• Automatic tilt

• Rapid pressurization up to 3 bar, permitting lower metal and flask temperatures

COMPETITORS

Most of our competitors machines have relatively weak casting chambers which cannot, thus, be pressurized up to 4 bar; gas pressure has to be applied slowly to the molten metal after pouring.This necessitates significant raising of both flask and metal temperatures in order to achieve adequate filling, leading to porosity and rough surface problems due to these high temperatures. Also – the manual tilt which is also a feature of other machines can lead to inadequate filling due to slow pouring or, alternatively, metal spillage due this this being too rapid.

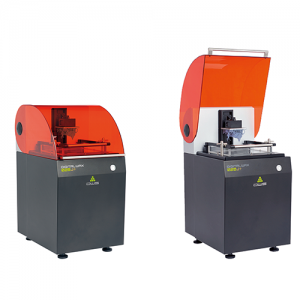

EXAMPLE OF MINISTRUCTURE

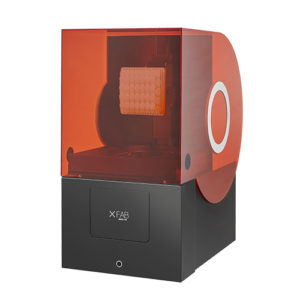

This compact machine, complete with oven and investment mixer,occupies no more than a space measuring 60 x 160 cms on a bench top and offers the facility of performing their own casting to goldsmiths, jewellery designers and small studios. An ideal way to produce individual castings from rapid-prototyping.

•Crucible Volume:

Au/Ag – A100.566 (20 cc) Graphit

Pt – A100.559 (10 cc) Ceramic

Steel/Pd – A100.564 (20 cc) Silicon carbide

•Crucible Life Time: Au/Ag – 90 / Pt – 15 / Steel/Pd – 10

•Melting Capacity:

Pt min. 20 g – max. 110 g

Au min. 30 g – max. 250 g

Pd min. 30 g – max. 90 g

Ag min. 30 g – max. 220 g

•Flasks Size:Ø min. 70 mm – Ø max. 90 mm / h min. 70 mm – h max. 90mm

•Working Frequency:70 kHz

•Optical Control And Thermocouple:

Pirometro ottico infrarosso (± 2% – 5%) per platino e acciaio fino a 2100°C – Termocoppia ad immersione tipo “S” fino fino a 1450°C per platino e argento/ Optical pyrometer infrared (± 2% – 5%) for Pt and Steel till 2100°C – Thermocouple “S” version till 1450°C for Pt and Ag

•Max Temperature:2150°C

•Water Cooling Supply:

ad acqua demineralizzata con resistività maggiore di 20K ohm/cm – 3 l/m – 3 bar con

impianto di raffreddamento a circuito chiuso (su richiesta cliente) / demineralized water with

resistivity over 20K ohm/cm – 2 liters/minute – 3 bar with system of cooling closed circuit

(optional)

•Compressed Air Supply:6 – 8 bar

•nert Gas Supply:Elio, Argon, Azoto / Helium, Argon, Nitrogen

Pompa Vuoto Esterna / External Vacuum Pump

8 m³/h – 0,005 mbar

•Dimension:600 x 500 mm – h 580 mm

•Weight:90 kg

•Guarantee:12 months